3M introduces Cubitron 3 Cut-Off Wheels for accident repair

With the introduction of the new 3M Cubitron 3 Cut-Off Wheels, 3M is setting new standards in abrasive technology. Developed for maximum productivity and efficiency, these cut-off wheels offer outstanding material removal and long-lasting performance, specifically designed to meet the demanding requirements of modern bodyshops.

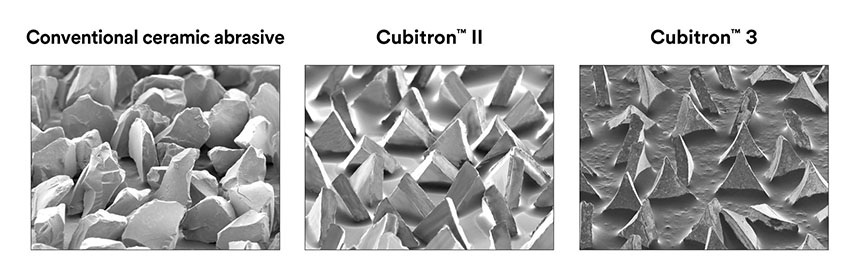

At the core of 3M Cubitron 3 Cut-Off Wheels is the revolutionary 3M Precision-Shaped Grain, engineered with sharp, angular structures that continuously fracture during use, forming fresh, sharp cutting edges. This allows the discs to slice faster and last longer compared to conventional ceramic abrasives.

Outstanding performance

- Removes up to 40% more material compared to 3M Cubitron II Cut-Off Wheels.

- 40% longer lifespan than the previous generation.

- Cuts through a wide range of materials, including high-strength steel, stainless steel, and mild steel.

The latest 3M Precision-Shaped Grain is built on proprietary advances in molecular bonding technology, ensuring an optimised mineral structure for superior durability and cutting efficiency. Unlike traditional ceramic abrasives, which tend to plow through material, generating excessive heat, 3M Cubitron 3 Cut-Off Wheels cut through metal with minimal heat build-up and reduced disc wear, extending both wheel life and workpiece quality.

3M introduces Cubitron 3 Cut-Off Wheels

3M Cubitron 3 Cut-Off Wheels are available in diameters of 75 mm, 100 mm, and 115 mm, ensuring compatibility with diverse workshop requirements.

The optimised technology of 3M Cubitron 3 Cut-Off Wheels not only increases workshop productivity but also supports resource-efficient working methods, aligning with 3M’s sustainability goals.

For more information, visit the 3M UK website.