Volta Trucks partners with Prodrive

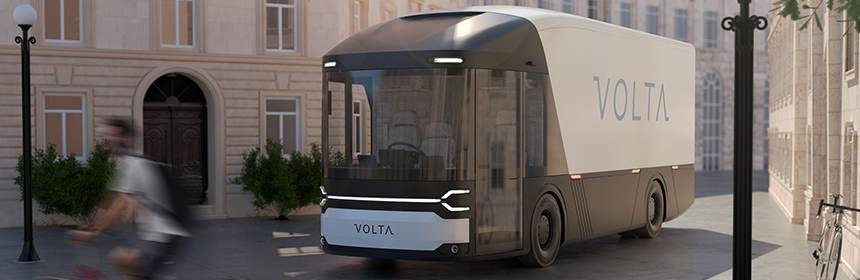

Prodrive is working with Volta Trucks to help engineer its 16-tonne electric HGV designed, not only to meet zero emissions requirements, but also to help keep vulnerable road users safer in crowded urban environments.

The Volta Trucks concept HGV positions its driver low down, centrally and forward of the front axle, to give uninterrupted vision at street level through 220 degrees. Prodrive will help develop the design into a drivable demonstrator by early summer 2020.

According to the London Mayor’s office, 23% of pedestrian and 58% of cyclist deaths in London involved a Heavy Goods Vehicle, despite HGVs making up only four per cent of road miles in London. By positioning the driver in the centre of the cab at eye level with a pedestrian; using extensive cabin glazing and replacing conventional rear-view mirrors with cameras, dangerous blind spots are eliminated. Passenger seating is arranged behind the driver, on either side. Transport for London already has a star rating system for truck visibility called the Direct Vision Standard, which comes into effect from October 2020. Prodrive believes the Volta truck will exceed that by such a margin as to set a new standard.

“Trucks face two major issues in an urban environment; not only are diesel engines rapidly becoming unacceptable but the category is disproportionately represented in accidents involving death and injuries among pedestrians and cyclists,” said Steve Price, the project leader at Prodrive. “Our client Volta Trucks has taken the design opportunity provided by the switch to electrification to re-imagine the layout of a conventional truck and address emissions and safety concerns simultaneously.”

To further reduce potential hazards, the truck uses bus-style doors on both sides with a slide/swing action to minimise intrusion into the path of pedestrians or cyclists and allowing the driver to easily access the central driving position. To maintain compatibility with existing loading bays, the rear of the truck and the tail lift arrangement follow conventional practice. This approach means the demonstrator vehicle can be created by combining an existing donor rear chassis ladder frame with the innovative cab and frontal arrangement.

Targets for the truck include a range of 100 miles, a top speed of 50 mph and a gradeability sufficient to briskly negotiate the on-off ramps and slip roads typical of urban elevated routes. To maximise payload, the new cab will be a composite-clad spaceframe structure, the composite panels using natural rather than carbon fibres. The vehicle can be produced in a range of sizes from 14-18 tonnes.